316 and 316L are both made of stainless steel, and the main difference lies in the carbon content:

Carbon content: The “L” in 316L stands for “Low Carbon”, so the carbon content of 316L stainless steel is lower than that of 316. Usually, the carbon content of 316 is ≤0.08%,

while that of 316L is ≤0.03%.

Corrosion resistance: 316L stainless steel with a lower carbon content will not produce intergranular corrosion (i.e. welding sensitization) after welding, which makes it perform

better in applications that require welding. Therefore, 316L is more suitable for use in highly corrosive environments and welded structures than 316 in terms of corrosion

resistance.

Mechanical properties: 316L has a lower carbon content, so it is slightly lower than 316 in terms of strength. However, the mechanical properties of the two are not much different

in most applications, and the difference is mainly reflected in the corrosion resistance.

Application scenarios

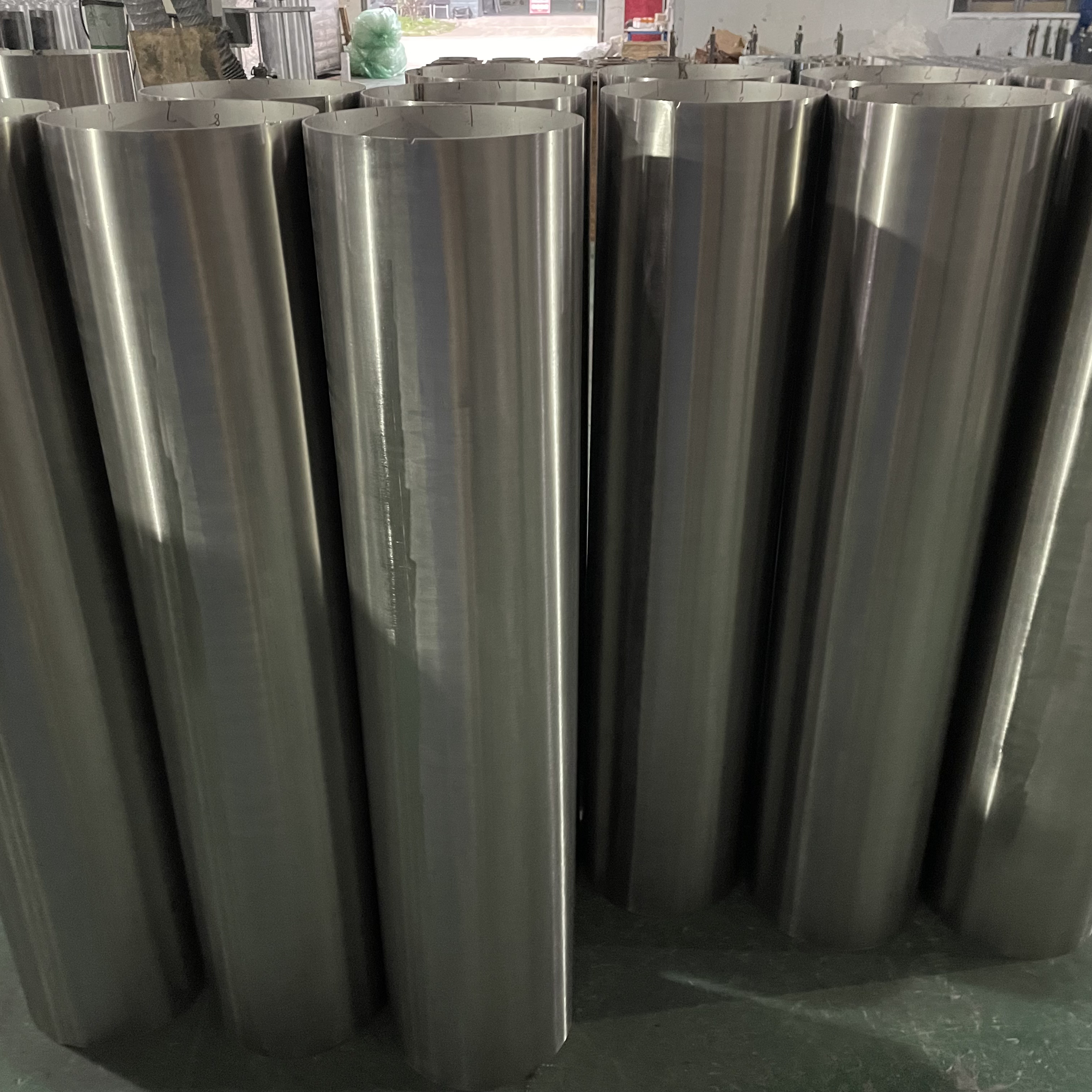

316: Suitable for environments that do not require welding and require high strength, such as chemical equipment.

316L: Suitable for environments that require welding and have higher requirements for corrosion resistance, such as marine facilities, chemicals, and medical equipment.

In summary, 316L is more suitable for applications with higher requirements for corrosion resistance, especially those that require welding, while 316 is suitable for occasions that

do not require welding and have slightly higher requirements for strength.

If you have any purchase requirements or any questions about the stainless steel bollards, please visit www.cd-ricj.com or contact our team at contact ricj@cd-ricj.com.

Post time: Nov-12-2024